Designers: Theresa Forshey and Meghan Hegarty

Client Coordinator: Cyeteese Garrett

INTRODUCTION:

Orange Enterprises is a community rehabilitation program that employs people with disabilities to perform a variety of jobs. One of the jobs commonly performed requires employees to place a clear, round sticker, called a wafer seal, along the edge of a folded piece of paper to hold it together for mailing. Currently, employees are handed a roll of wafer seals, the mailings, and a cardboard template. A roll of wafer seal is similar to a roll of tape, but with the stickers mounted to a backing. However it is difficult for anyone, with or without a disability, to remove the stickers from the tape. The client then must slide the mailing into the template, which has semi-circles cut out on the edges to indicate where the wafer seal should go, and attach the wafer seal.

Our client is an employee with poor vision, limited motor control, and use of only one hand to perform this task. It is difficult for him to remove the wafer seal from the roll and to use the template correctly. Furthermore, it is hard for him to see the clear wafer seal sticker. As a result, he cannot effectively do this task independently.

Our goal was to develop a Wafer Sealing Aid so that our client can perform this task at work. This will lead to: (1) greater productivity due to faster sealing times, (2) a decrease in the number of rejected mailings resulting from misplaced wafer seals, and (3) greater independence due to a decrease in the need for supervision and help. Overall, this will serve to increase the number of units completed per hour, resulting in greater income for the client.

SUMMARY OF IMPACT:

The client coordinator states that, “The wafer seal device will allow opportunities for clients with vision impairments, limited range of motion, and/or fine motor skills to perform the task of wafer sealing. The wafer seal device may be used as a training tool as well.”

TECHNICAL DESCRIPTION:

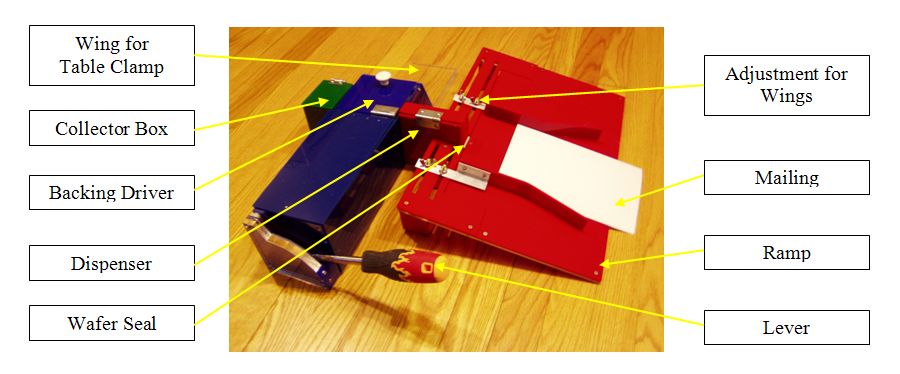

Our device, shown in figure 1, uses a ratcheted lever system to dispense a single wafer seal for each pull of the lever. The client then slides a mailing into place under the exposed seal, using a ramp and guide arms for alignment, and sticks the wafer seal onto the mailing.

With each pull of the lever, the wafer seal roll is pulled a fixed distance through the dispenser. A ratcheting system pulls the roll in only one direction for each pull/push cycle of the lever. As the backing is pulled through a 180 degree turn just in front of the ramp, the wafer seal becomes partially detached from the backing, making it easy for the client to access it. The empty backing is then collected in the collector box. The client places the mailing on the ramp, right under the partially exposed wafer seal, and the alignment wings allow for correct placement relative to the wafer seal dispenser. At this point, it is easy to stick the wafer seal onto the mailing and complete the operation.

With this device, the client can repeatedly execute the same steps for this task. The steps are: turn the lever, slide the mailing up the ramp, push the wafer seal onto the mailing, slide the mailing back down, and fold the wafer seal over onto the other side of the mailing. While this process consists of many steps, the client is able to perform the task effectively.

The device is safe, adjustable and easy for the job coaches to setup. There is a hinge door with a handle that makes loading the tape into the backing driver easy. The box for this mechanism is long in order to increase stability and allow the lever to be easily reached. The device is stable without a table clamp, but the wing can be clamped to the table as extra precaution. The job coach can adjust the wings, depending on the mailing size and orientation.

The device is made from colored acrylic to provide a professional look as well as making it easy to remove misplaced wafers. The total cost of the project is $183.

University Operator: (919) 962-2211 | © 2024 The University of North Carolina at Chapel Hill |